Robot Zero Position

Introduction

Robots control each axis motor operation through closed-loop servo systems, with controllers precisely controlling each motor’s operating state through commands. Pulse encoders mounted on motors can provide real-time feedback of motor operation signals to robot controllers. During robot motion, controllers continuously receive and analyze signals returned by encoders to achieve precise control of robot movement.

Controllers must accurately know the zero position of each axis to correctly analyze position information returned by encoders. Only after determining the zero reference can robots maintain position consistency and repeatability during each use.

Zero Point Data Storage Mechanism

During normal robot operation, zero positions and robot joint positions are saved and maintained using internal batteries when controllers are normally powered down.

Each time robots are normally shut down, this data is saved. Each time power is restored, robots directly read backed-up data for identification to ensure consistency with the state before power loss.

After robots experience impacts, battery power loss, or long periods of non-use, zero points may shift or be lost. In such situations, robots need zero point calibration to reset zero positions, ensuring robots can work normally.

Hazards of Zero Point Loss

When robots continue working with lost zero points, multiple serious consequences occur.

-

Robot joint axes may work beyond software limit ranges, which is a very dangerous situation.

-

Robots cannot reach specified positions because different zero positioning causes different robot end positions under the same joint angle conditions.

-

Robots cannot move specified distances in specified directions (such as inability to accurately move 1 meter).

-

During hand-eye calibration and other external parameter calibrations, software calculates multiple key points robots need to reach based on calibration algorithms. With lost zero points, robots often cannot accurately reach these points, ultimately causing errors in external parameter calculation results and affecting robot grasping precision and work quality.

Zero Point Checking Methods

There are multiple methods to detect whether robot zero points are lost. The following are two most commonly used and effective detection methods:

-

Use the teach pendant to adjust all robot axes to 0°, then observe whether nameplates on each robot axis are aligned. If not aligned, robot zero points are lost.

-

Control robots to move a certain distance in specified directions, observing whether robot movement distances match theoretical distances. If significant deviations exist, zero point problems may exist.

Zero Point Calibration

Zero point calibration is a precise technical process whose essence is setting motor-specific position corresponding encoder values as zero position encoder values. This process is also called "zeroing."

Re-zeroing actually changes software position calculation references. It should be noted that re-zeroing will cause actual position points in previously taught work programs to change. Therefore, after zero point calibration, related work points may need to be re-taught.

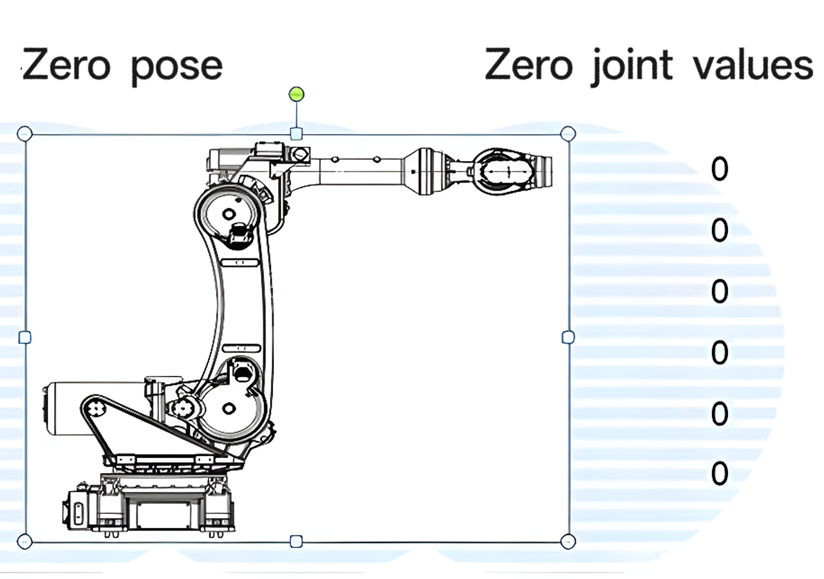

Zero Position Pose

When performing zero calibration, robot axes need to move to specific standard positions called mechanical zero positions. It should be noted that different manufacturers have different definitions of "mechanical zero position." Mechanical zero positions are usually preset by manufacturers, generally positioned through nameplate markings or special calibration fixtures, and not all axes are at 0°.

In this example pose, robot joint values for all axes are 0°, specifically:

| Axis Number | Joint Value |

|---|---|

Axis 1 |

0° |

Axis 2 |

0° |

Axis 3 |

0° |

Axis 4 |

0° |

Axis 5 |

0° |

Axis 6 |

0° |