Absolute Positioning Accuracy Error

Introduction

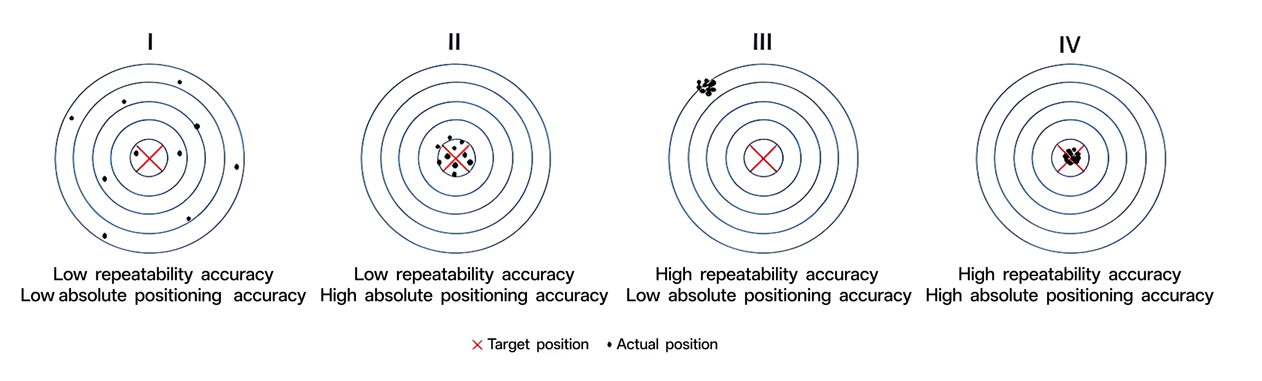

When industrial robots perform tasks, their positioning capability is one of the important indicators for measuring robot performance. Robot positioning accuracy mainly consists of two aspects: absolute accuracy and repeatability.

Absolute accuracy refers to the difference between the actual pose reached by the robot hand and the ideal pose required to be reached. This is an absolute measurement relative to a reference frame, reflecting the overall positioning accuracy of the robot system. When we send a target pose command to the robot, the deviation between the actual pose eventually reached by the robot and the theoretical target pose is the absolute accuracy error.

Repeatability refers to the error measurement between consecutive motion trajectories when the robot executes the same motion pose command multiple times. If a robot repeatedly executes a given pose command, the distance it travels each time is not identical, but varies around an average value. This average value represents absolute accuracy, while the magnitude of variation represents repeatability. This indicator reflects the stability and consistency of the robot system. Even if absolute accuracy has deviations, if the robot’s deviations are relatively consistent each time, its repeatability can still be very high.

Main Factors Affecting Absolute Accuracy

-

Manufacturing accuracy of mechanical structure: The size of joint clearances directly affects transmission accuracy. Manufacturing errors in transmission system components such as reducers and couplings produce cumulative effects, while insufficient rigidity of the robot arm itself causes deformation under load. These physical characteristics together determine the upper limit of the robot’s fundamental positioning capability.

-

Control system accuracy: Encoder resolution determines the precision of pose feedback; the higher the resolution, the more accurate the pose detection. Numerical calculation accuracy in control algorithms, accuracy of interpolation algorithms, and dynamic response characteristics of servo systems all directly affect final positioning accuracy. Especially during multi-axis coordinated motion, control errors from each axis may produce additive effects.

-

Environmental factors: Temperature variations cause thermal expansion and contraction that changes the robot’s geometric dimensions and joint parameters, which is particularly evident in large robots. Vibrations at the work site interfere with robot stability, and electromagnetic interference may affect encoder signals and normal operation of the control system, thereby indirectly affecting positioning accuracy.

Methods to Improve Absolute Accuracy

-

Robot calibration: Identify and compensate for kinematic parameter errors through calibration, including deviations in link lengths, joint offsets, transmission ratios, and other parameters. Modern industrial robots typically come equipped with calibration functions that can be recalibrated as needed to restore accuracy.

-

External sensor closed-loop control: Use high-precision sensors such as vision systems and laser ranging to monitor robot pose in real-time, forming closed-loop feedback control. This method can compensate for system errors in real-time and is particularly suitable for high-precision applications.

-

Regular maintenance: Establish standardized maintenance schedules, replace worn mechanical components in time, maintain good lubrication of transmission systems, and ensure stable operation of control systems.