Smart Camera

A milestone breakthrough in industrial vision! TransferTech officially releases the upgraded 3D smart camera series, integrating powerful computing capabilities directly into the camera body, replacing the traditional "camera + industrial PC + graphics card" system architecture. Through integrated design, it demonstrates significant advantages in space saving, cost optimization, and deployment flexibility, providing customers with a new choice.

Smart Camera Advantages

Significant Cost Reduction: Eliminating Industrial PC, Camera Edge Computing

TransferTech has innovatively integrated high-performance computing modules into the camera body. The smart camera comes with 16GB of RAM and 128GB of storage space, eliminating the traditional device’s dependency on external industrial PCs. The highly integrated design not only greatly improves device deployment flexibility but also directly reduces the procurement and maintenance costs of industrial PCs and supporting equipment (such as graphics cards, switches, and cabinets) while maintaining the camera’s basic performance.

The smart camera integrates the full version of Epic Pro visual software and ATOM algorithm platform, achieving efficient coordination of imaging, recognition, obstacle avoidance, and planning within the same device. Through comprehensive optimization of camera hardware and underlying algorithms, it enables running high-complexity point cloud processing algorithms and deep learning algorithms at the edge.

Application Scenario |

Visual Beat |

Bag/Box Depalletizing |

1.5s |

Random Bin Picking |

1.9s |

Assembly |

1.4s |

Regarding data storage concerns, the 3D smart camera supports efficient and stable data storage to external devices or servers through local area networks, while being compatible with various operating systems such as Windows, Ubuntu, and cloud servers, meeting users' flexible needs for data storage and management, further enhancing the device’s practicality and scalability.

| Traditional Camera with External Industrial PC | 3D Smart Camera | |

|---|---|---|

Cost |

Camera + Industrial PC + Cabinet + Graphics Card + Switch + Energy Consumption |

Camera Price Only |

Space Usage |

Industrial PC + Cabinet + Cables + Switch |

Camera and Cables Only |

Computing Dependency |

Dependent on External Industrial PC |

Built-in Processing Unit, Supports Independent Operation |

Installation Efficiency |

Hardware Installation, Software Deployment, Programming Debugging |

Built-in Software, Two Cables, Plug-and-Play, Quick Deployment |

Energy Consumption |

300W+ |

4W-36W |

Failure Risk |

Hard Drive Failure, Graphics Card Damage, Frequent Crashes |

None |

Stability Optimization: More Stable and Reliable than Separate Industrial PC Deployment

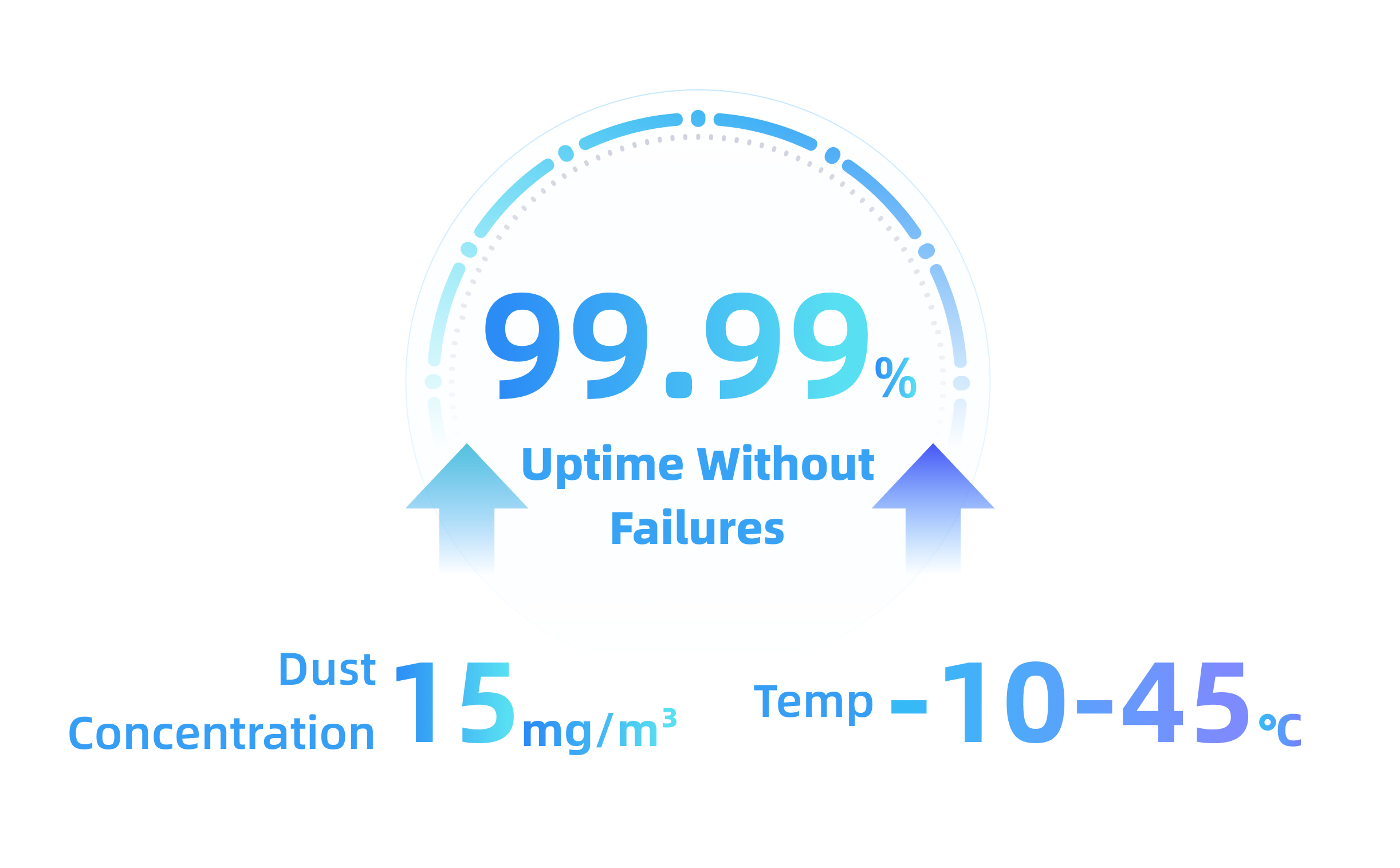

The 3D smart camera relies on TransferTech’s self-developed integrated hardware and software architecture, maintaining strong stability and reliability even in extreme environments. The highly integrated SOC fundamentally eliminates common issues in traditional industrial PCs such as hard drive failures and graphics card damage. The 3D smart camera provides IP65 protection, significantly reducing failure risks caused by fan dust accumulation and water condensation. This innovative design ensures the device can operate stably for extended periods, providing continuous and reliable support for industrial production.

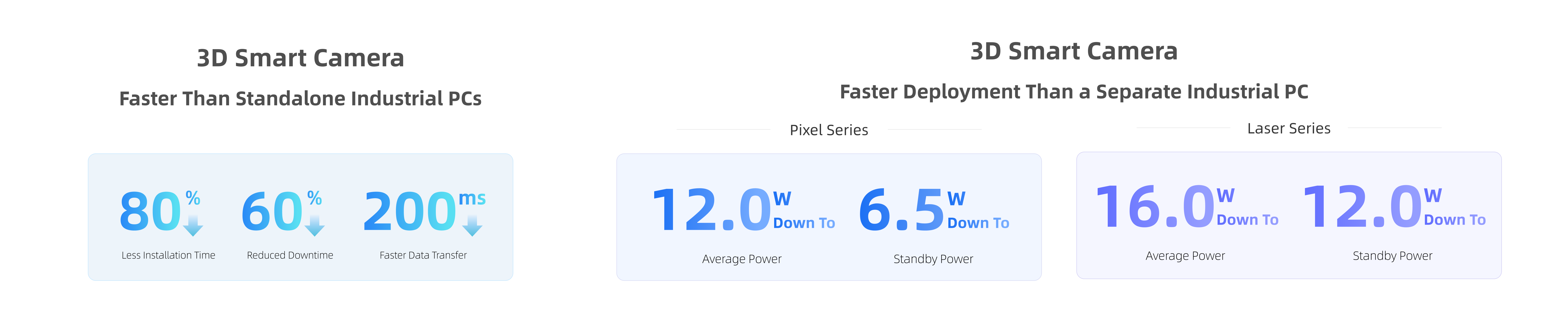

Meanwhile, the 3D smart camera can operate independently without an industrial PC, supporting plug-and-play, further reducing wiring requirements and improving deployment flexibility. According to calculations, TransferTech’s smart 3D industrial camera installation time is reduced to 1/5 of traditional solutions; supports quick replacement, reducing failure downtime by over 60%; the built-in high-performance SOC enables edge fast processing, with internal data transmission reaching 10 Gigabit, 10 times that of traditional solutions, reducing transmission time by 200ms+; in terms of energy efficiency, the Pixel series 3D smart camera’s average power consumption can be as low as 12W, with standby power consumption as low as 6.5W, while the Laser series 3D smart camera’s average power consumption can be as low as 16W, with standby power consumption as low as 12W.

In terms of maintenance and debugging, the 3D smart camera supports multi-platform device connection, allowing users to easily achieve cross-platform debugging and management through computers, phones, or tablets. Engineers can monitor the operating status of cameras in the factory in real-time, check device parameters and promptly discover potential issues, greatly improving management efficiency.

Additionally, the device has built-in multiple redundant backup mechanisms, ensuring the system remains in a stable operating state even under extreme conditions. Through this high-reliability design, the device’s availability and stability have been significantly improved, providing solid support for efficient operations in industrial scenarios. Actual test data shows that the device maintains a 99.99% failure-free operation rate in environments with dust concentration of 15mg/m³ and temperatures from -10℃ to 45℃.

Improved Space Utilization: 3D Smart Camera is an Ideal Choice for Composite Robots

In composite robot scenarios, device space occupation and energy efficiency are crucial. The 3D smart camera, with its unique advantages, becomes an ideal choice for this scenario.

The camera body is compact and exquisite, greatly saving space and perfectly adapting to the limited installation space of composite robots, eliminating the need for additional space for external devices, making the robot’s overall structure more concise and compact. Its highly integrated design is a major highlight, capable of independently completing the entire process of image acquisition, visual algorithm processing, motion planning, and obstacle avoidance without external industrial PCs, avoiding the problems of volume increase and complex wiring brought by external devices, further improving space utilization.

In terms of energy consumption, the camera’s low-power design gives it outstanding advantages in battery life, with low energy consumption benefiting long-term operation of composite robots, reducing the hassle of frequent charging, and meeting the high requirements for battery life in mobile operations of composite robots. Even in complex industrial field environments, it can operate stably, providing precise visual support for composite robots.

Using Smart Camera

For more information about smart cameras, please visit Using Smart Camera.