Epic Eye Pixel Welding

Safety Instructions

Safety Statement

-

Before using this product, please read the product manual and correctly understand the safety information. Failure to comply with the safety instructions may result in equipment damage or serious injury or death.

-

Transfer will not be liable for any legal responsibility for personal safety accidents or property losses caused by non-compliance with this manual or improper operation of the product.

Precautions

-

Avoid using the camera in dusty environments, areas with strong electromagnetic interference, direct strong light exposure, or environments outside the specified temperature and humidity range.

-

Do not look directly at the projection beam while the camera is operating to avoid eye damage.

-

Ensure the camera window is clean. Use a dust-free cloth for cleaning if needed.

-

Do not install, disassemble, or clean the camera while it is powered on.

-

Avoid severe impact or dropping during transportation and installation.

-

If any abnormal conditions are detected (such as unusual noise, odor, or smoke), immediately cut off the power and inspect.

-

Modification of the camera and its power cable is strictly prohibited.

Packing List

When unpacking, please check if the camera and its accessories have any damage, rust, or impact marks, and verify that all items match the package contents list. If any damage, rust, impact marks are found on the camera or its accessories, or if the actual items do not match the package contents list, please contact Transfer.

Technical Specifications

Technical Parameters

System Parameters |

Baseline Length |

85mm |

Recommended Working Distance |

300mm~700mm |

|

Optimal Working Distance |

500mm |

|

Near Field of View |

295mm×175mm@0.3m |

|

Far Field of View |

670mm×390mm@0.7m |

|

VDI/VDE Measurement Accuracy(1) |

0.1mm@0.5m |

|

Z-axis Single Point Repeatability |

0.03mm@0.5m |

|

Pixel Count |

2.3 million |

|

Resolution |

1920×1200 |

|

Typical Acquisition Time |

0.2s~0.7s |

|

Power Supply |

24V ⎓ 2.5A |

|

Peak Power |

32W |

|

Average Power Consumption |

4.5W |

|

Standby Power Consumption |

2.5W |

|

Hardware Parameters |

Dimensions(L*W*H) |

130mm×71mm×79mm |

Installation Method |

Fixed Installation/End-of-Arm Installation |

|

Communication Interface |

Gigabit Ethernet |

|

Light Source |

Blue LED(440nm) |

|

2D Camera |

Monochrome |

|

Environmental Parameters |

Operating Temperature Range |

0℃~50℃ |

Operating Humidity Range |

20%~90% RH No Condensation |

|

Protection Rating |

IP65 |

|

Cooling Method |

Passive |

|

Weight |

1.01kg |

|

Storage Temperature |

-20℃~70℃ |

|

Storage Humidity |

20%~90% RH No Condensation |

(1): Based on VDI/VDE 2634 Part II standard

If the parameter content in this manual is updated, no separate notice will be provided. Please refer to the latest published data for accuracy.

Installation and Connection

Installing the Camera

Mounting Method 1:

Mounting Method 2:

|

Mounting the Camera on the Bracket

Mounting Method 1:

Mounting Method 2:

|

Cable Connections

Connection Notes

-

Do not connect or disconnect while powered on. Ensure all cables are connected before powering on.

-

Align plugs with sockets before slowly tightening, avoid excessive force when connecting or disconnecting.

-

Use cable ties to secure camera network cable, power adapter, and power cord.

-

When using a router, insert all network cables into the router’s LAN ports.

-

When using a router or switch, it is recommended to use Gigabit router, Gigabit switch, and Gigabit RJ45 cables.

Wiring Connections

-

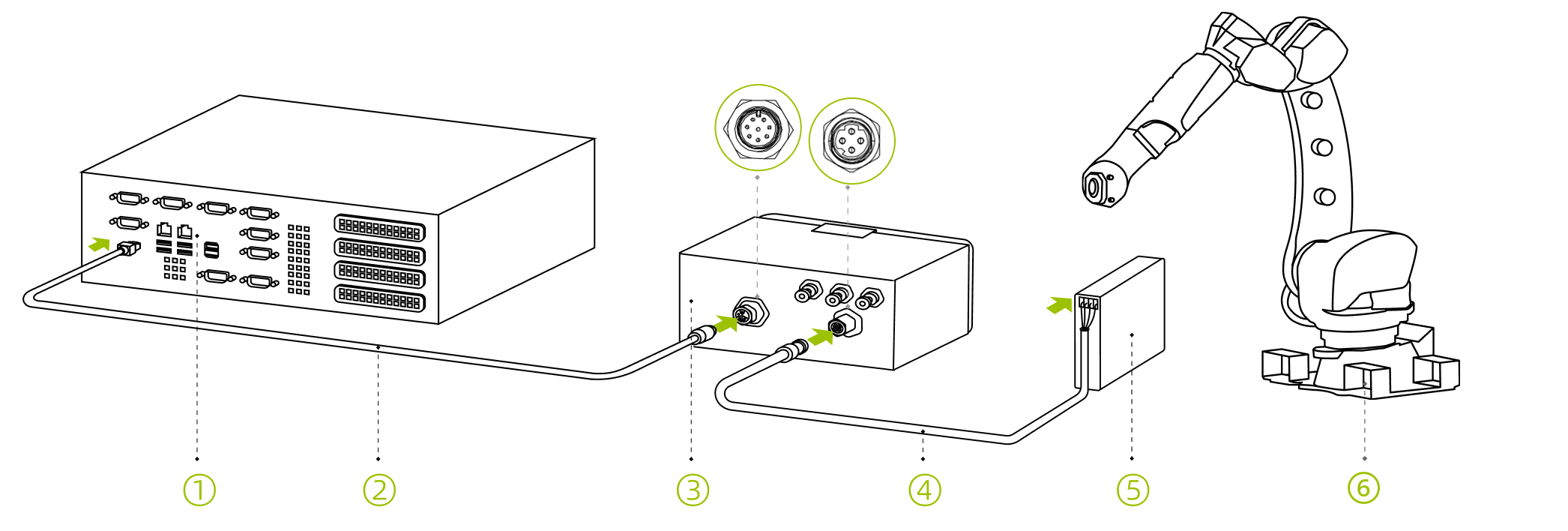

Camera Directly Connected to Industrial PC

-

Industrial PC; 2. Camera Ethernet Cable; 3. Camera; 4. M8-4Pin-10m DC Power Cable; 5. Rail Power Supply; 6. Robot

-

-

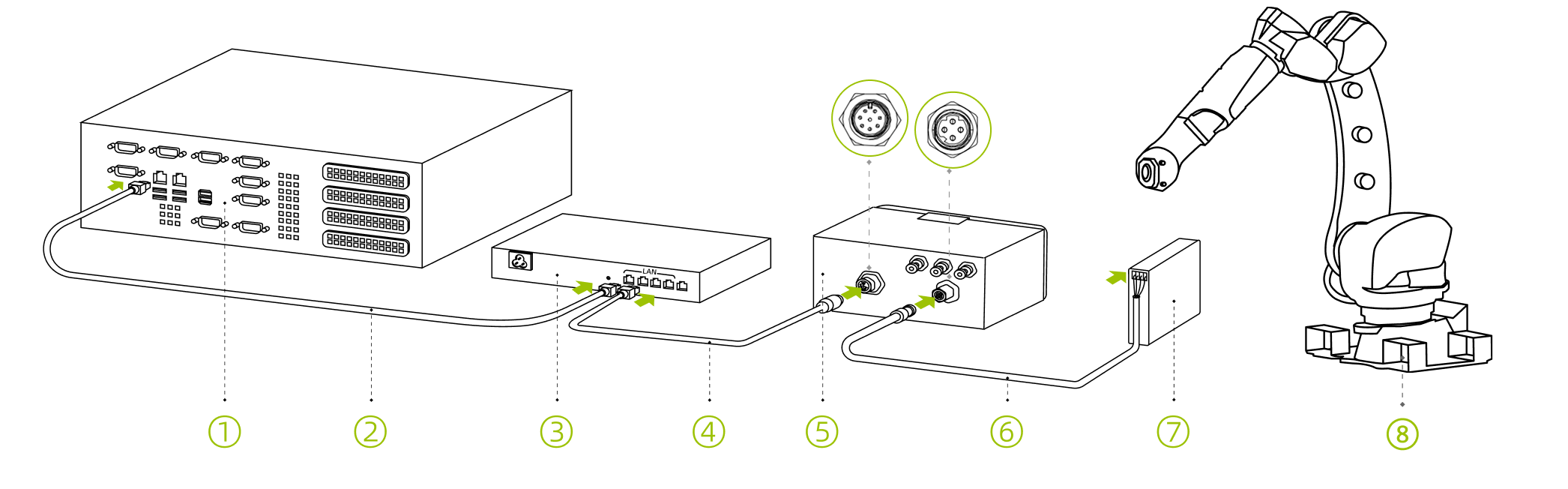

Camera Connected to Industrial PC via Switch

-

Industrial PC; 2. Ethernet Cable; 3. Switch; 4. Camera Ethernet Cable; 5. Camera; 6. M8-4Pin-10m DC Power Cable; 7. Rail Power Supply; 8. Robot

-

Smart Camera Connection Cable

Connection Notes

-

Prepare a display device that can be connected to the camera, such as an industrial PC or laptop.

-

Disconnect the display device after debugging.

Connection Methods

-

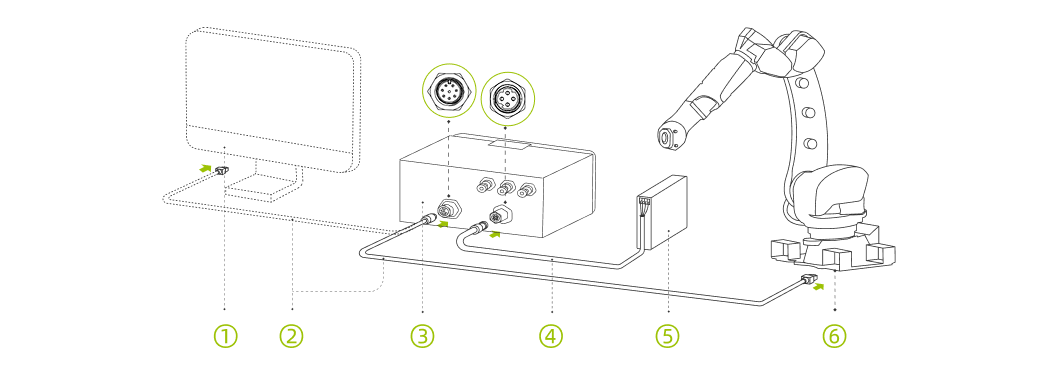

Direct Connection between Smart Camera and Robot

-

Display Device (Debug Connection); 2. Camera Network Cable; 3. Camera; 4. M8-4Pin-10m DC Power Cable; 5. Rail Power Supply; 6. Robot (Running Connection)

-

-

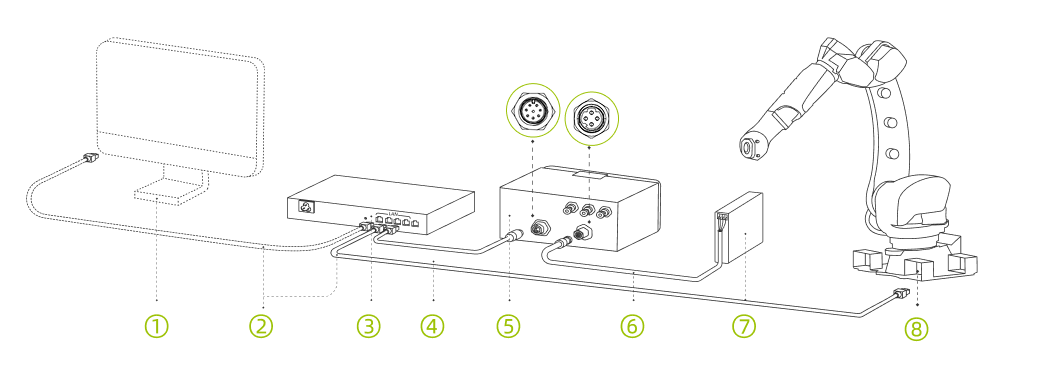

Connection between Smart Camera and Robot via Switch

-

Display Device (Debug Connection); 2. Network Cable; 3. Switch; 4. Camera Network Cable; 5. Camera; 6. M8-4Pin-10m DC Power Cable; 7. Rail Power Supply; 8. Robot

-

Power Cord Technical Specifications

Physical Parameters

Model |

Straight |

Angled |

CBL-PWR-8-20M CBL-PWR-8-30M |

CBL-PWR-8-10M-LU CBL-PWR-8-20M-LU CBL-PWR-8-30M-LU |

|

Color |

Black |

|

Outer Sheath Material |

PVC |

|

Outer Diameter |

6.5(+0.15/-0.15)mm |

|

Connector |

M8, straight or angled, 4-pin loose wire end |

|

Conductor Diameter |

0.5 mm² |

|

Static Bending Radius |

65 mm |

|

Dynamic Bending Radius |

80 mm |

|

EMI shielding effectiveness |

Aluminum foil, metal woven mesh, double-layer shielding |

|

Safety |

RoHS Compliant Flame Rating: V-1 |

|

Cable Carrier Test |

Bending Radius: 65mm Stroke: 1000mm Speed: 3200 mm/s Cycles: ≥ 5 million |

|

Compatible Camera Models |

Pixel Welding, Pixel Pro, Pixel Mini |

|

Dimensions

Unit: mm

Model |

L |

|---|---|

CBL-PWR-8-20M |

20m |

CBL-PWR-8-30M |

30m |

Model |

L |

|---|---|

CBL-PWR-8-10M-LU |

10m |

CBL-PWR-8-20M-LU |

20m |

CBL-PWR-8-30M-LU |

30m |

Ethernet Cable Technical Specifications

Physical Parameters

Model |

Straight Head |

Angled Head |

CBL-ETH-20M CBL-ETH-30M |

CBL-ETH-10M-LU CBL-ETH-20M-LU CBL-ETH-30M-LU |

|

Color |

Black |

|

Outer Sheath Material |

TPU |

|

Filler |

Cotton Yarn |

|

Outer Diameter |

5.9 (+0.1/-0.2) mm |

|

Connector |

M8, straight or angled, 4-pin Open End |

|

Conductor Diameter |

26 AWG |

|

Static Bending Radius |

60 mm |

|

Dynamic Bending Radius |

50 mm |

|

EMI shielding effectiveness |

Aluminum foil, metal woven mesh, double-layer shielding |

|

Safety |

RoHS Compliant Flame Resistance: V-1 |

|

Drag Chain Test |

Bending Radius: 50 mm Stroke: 1000 mm Speed: 3200 mm/s Cycles: ≥ 1 million |

|

Compatible Camera Models |

Pixel Welding, Pixel Pro, Pixel Mini |

|

Calibration Board Installation

|

Maintenance and Care

Regular maintenance of industrial 3D camera hardware is crucial for ensuring stable operation and measurement accuracy. It not only extends equipment service life but also helps in timely detection and prevention of potential issues, reducing equipment failure rates and ensuring continuous stable operation of production lines. Please strictly follow the maintenance regulations and keep proper records.

Daily Inspection

-

Check power supply status regularly, inspect power cable connections for proper contact, ensure stable power voltage output meeting power supply specifications. When necessary, use UPS (Uninterruptible Power Supply) to prevent unexpected power outages.

-

Verify network connection stability and ensure network transmission rates meet requirements.

-

Monitor working environment temperature and humidity for compliance with specifications, ensure good ventilation for proper camera cooling.

-

Inspect camera housing integrity, ensure no damage, deformation, or corrosion, and avoid risks of scratching or collision with surrounding objects.

-

Check camera mounting and adapter fixtures for tightness, ensure no deformation, looseness, or wobbling.

-

Inspect cable connector stress conditions, ensure reasonable cable routing without excessive bending, and check cable sheathing for aging or cracking.

Regular Cleaning

Clean the camera regularly to ensure the lens is clean, free from visible dust and stains. Use a clean soft cloth to wipe the camera body, and clean the camera lens with a clean, soft, lint-free cloth dampened with lens cleaner or glass cleaner to avoid scratching the lens.

Cautions

-

Power off the equipment before cleaning.

-

Do not use alcohol or other corrosive cleaning agents.

Storage and Transportation

-

Use original packaging or professional shock-proof cases for camera storage and transportation.

-

Ensure storage environment temperature and humidity meet standards.

-

Avoid severe vibration and impact, keep away from strong magnetic fields.

-

Maintain correct placement orientation, avoid direct exposure of lens to strong light sources such as sunlight.

-

Conduct thorough cleaning before long-term storage, perform regular power-on checks (every 3 months).

Technical Support Channel

For technical support, please call the official service hotline 4000-191-161, press 3 for technical support according to voice prompts.

Legal and Compliance

Disclaimer

Transfer will not be liable for any legal responsibility for personal safety accidents or property losses caused by user non-compliance with safety regulations, improper operation, or unauthorized modification of the camera or power cables.